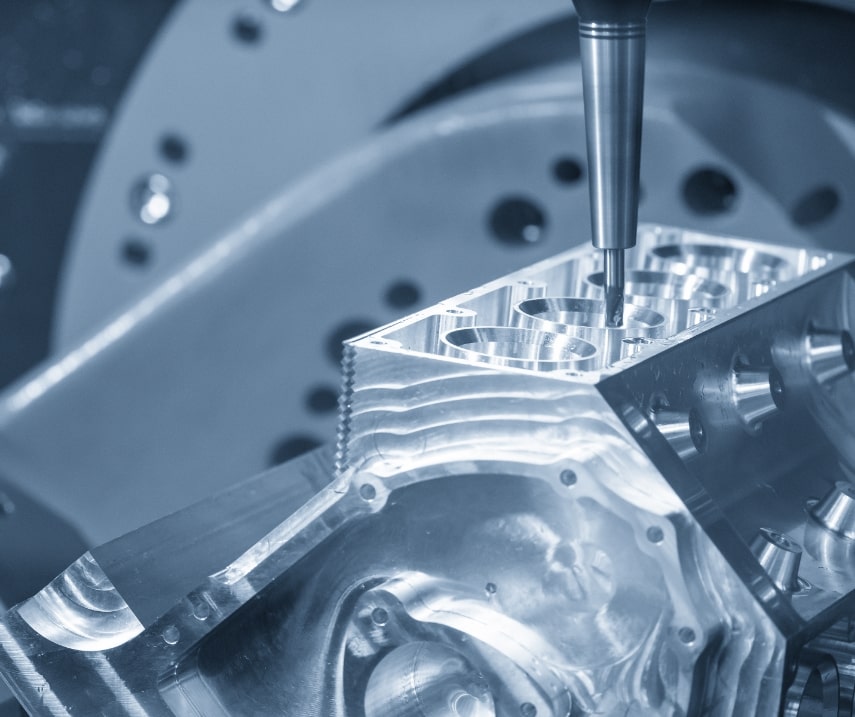

Diecasting in Malaysia has actually emerged as an important sector, playing a substantial function in the country’s production and commercial markets. Understood for its efficiency and accuracy, die casting includes injecting molten steel into molds to produce get rid of high dimensional accuracy and extraordinary surface high quality. This process is extensively made use of across industries such as auto, electronics, aerospace, and consumer goods. In Malaysia, the Diecasting market has obtained prestige as a result of the country’s critical place, competent workforce, and concentrate on sophisticated production innovations. With an increasing demand for light-weight, durable, and affordable elements, Diecasting continues to be a driving force behind Malaysia’s industrial growth and global competitiveness.

One of the main reasons Diecasting has actually prospered in Malaysia is its application in the auto industry. As one of the biggest factors to the Malaysian economic situation, the automobile sector depends heavily on die-cast elements for engine components, transmission systems, and structural components. Light weight aluminum die casting, specifically, is popular for generating light-weight and corrosion-resistant parts that boost car efficiency and fuel efficiency. Firms in Malaysia have adopted advanced Diecasting modern technologies, such as high-pressure and vacuum cleaner Diecasting, to fulfill rigorous high quality requirements required by international auto manufacturers. This focus on innovation has made it possible for Malaysian die casting companies to become essential distributors in the global automotive supply chain.

Past the automotive sector, die casting in Malaysia is essential to the electronic devices and telecoms industries. The country, called a hub for electronics producing, needs high-precision elements for products such as smartphones, computer systems, and interaction devices. Diecasting is the preferred technique for producing elaborate parts like heatsinks, adapters, and real estates as a result of its capacity to supply intricate forms with premium thermal and electric homes. Malaysian producers have leveraged advanced tools and strict quality control processes to fulfill the needs of global electronic devices titans. This harmony between die casting and electronics manufacturing has contributed substantially to Malaysia’s online reputation as a leader in high-tech production.

Sustainability and efficiency are increasingly ending up being centerpieces for the high pressure diecasting malaysia. Makers are purchasing eco-friendly methods, such as reusing scrap steel and minimizing energy usage throughout the spreading procedure. Advanced simulation software application is used to optimize mold designs and minimize material waste, boosting both cost-effectiveness and sustainability. Using light-weight products, such as magnesium and aluminum alloys, straightens with global initiatives to decrease carbon exhausts, specifically in the vehicle and aerospace markets. By embracing eco-friendly production practices, Malaysian die casting companies are not just fulfilling regulatory needs however likewise placing themselves as responsible gamers in the global market.

Malaysia’s Diecasting sector take advantage of a strong community of research study, growth, and collaboration. Partnerships in between manufacturers, universities, and federal government companies have actually driven technology and skill advancement within the field. Programs concentrated on sophisticated manufacturing modern technologies, such as automation and robotics, are equipping the labor force with the know-how required to remain competitive in a swiftly evolving worldwide market. Additionally, the federal government’s support via policies and rewards, such as tax breaks and grants, has motivated investment in advanced centers and research initiatives. These efforts have enhanced Malaysia’s setting as a regional hub for die casting and progressed production.

Diecasting in Malaysia is an important sector that remains to sustain the nation’s economic and industrial growth. Its applications in automotive, electronic devices, and other fields highlight its value in producing top notch, affordable parts. By welcoming development, sustainability, and collaboration, Malaysian Diecasting business are well-positioned to satisfy the obstacles of a progressively competitive international market. As industries worldwide demand light-weight and precision-engineered parts, Malaysia’s Diecasting sector is poised to play an essential function fit the future of manufacturing. With a focus on high quality, performance, and environmental responsibility, die casting continues to be a cornerstone of Malaysia’s commercial success.